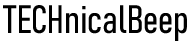

A Finnish technology startup, Hyperion Robotics has secured €3 million in seed funding. The company specializes in sophisticated automation and environmentally friendly technologies for concrete and the construction sector.

Lifeline Ventures took the lead in the funding round (which also backed Huuva and Oura). It ranks among the top VC firms in both the Nordics and Europe. Goldacre, a London-based VC focused on the sustainable built environment and its first investor, Impact VC Übermorgen from Switzerland, PC Rettig & CO Impact, a Finnish/Swedish family office with an industrial background, and the climate-focused VC and accelerator Katapult from Norway are all co-investors in the round. As the original investor in Hyperion, Katapult is reaffirming its support with a new investment in this round.

With the help of this funding, Hyperion Robotics will be able to expand its R&D skills, advance its software and material technologies, and introduce its first Micro-factories to major global projects. With this investment, the business will expand the use of mobile 3D printing micro-factories worldwide.

Along with the funding round, Kai Backman, a partner at Lifeline, will become a board member. “We are thrilled to invest in Hyperion, a business that has developed a highly distinctive method of integrating software and additive manufacturing in manufacturing concrete.”

“Hyperion has a unique advantage to scale up its Micro-factories and have a significant effect in this very conservative market because of the combination of highly optimized buildings, robotically constructed, and made with sustainable concrete,” he said.

About 8% of the carbon dioxide emissions in the world come from cement. The building industry’s high carbon intensity must be reduced to address the climate catastrophe, according to Alexander Langguth, General Partner of Übermorgen Ventures.

In addition, Alexander added that “Hyperion Robotics developed a key technology that reduces carbon dioxide emission in two ways: It permits the use of more complex structures, which can use up to 75% less material than conventional structures, and It recycles industrial waste to produce low-carbon cement mixtures.”

“Over the past few decades, construction has faced many difficulties, including logistical difficulties that contribute to project delays, excessive prices, and health and safety issues,” stated Fernando De los Ríos – CEO of Hyperion Robotics. Its effects on the environment and society are significant at the same time.

Fernando stated, “By implementing 3D printing technologies to streamline building processes and enhance sustainability over the lifecycle of their projects, construction organizations may generate higher growth and productivity.

In Espoo, Finland, in 2018, Ashish Mohite, Henry Unterreiner, and Fernando De los Rios established Hyperion Robotics. One of the biggest but most dated industries is building, which is transformed by it. Concrete emissions from the construction account for 8% of annual global CO2 emissions, or 2.8 billion tonnes of CO2.

Hyperion is delivering an automated and sustainable solution to the industry by fusing large-scale 3D printing with low-carbon concrete. To improve productivity and lower carbon emissions from industrial and infrastructure projects worldwide, it has been collaborating with top industrial global giants including Iberdrola and Metso Outotec.

Image Credit: Hyperion Robotics